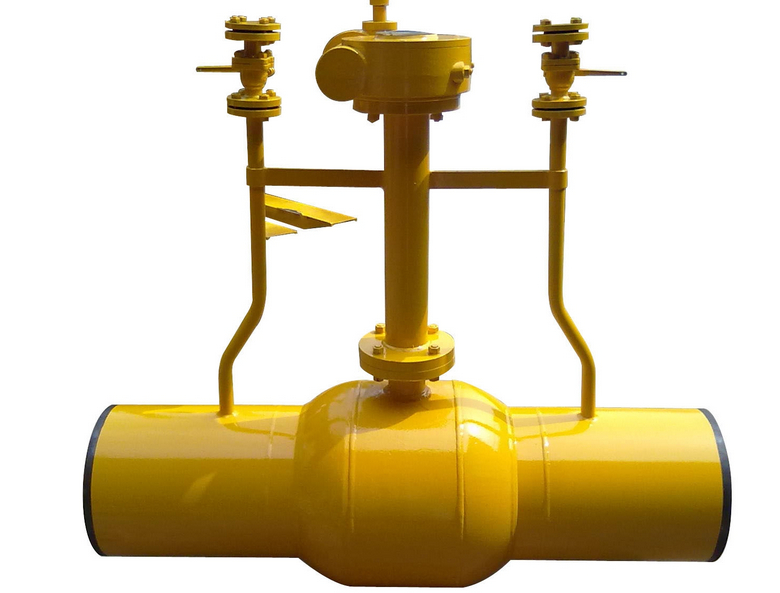

Features and Advantages of Buried Full Welded Ball Valves

1. Because of the welded structure, buried full welded ball valves are easy to insulate with light weight.

2. The body and stem are all made of stainless steel with two anti-flying o-rings to ensure the rigor. Also, the upper container can be replaced, so buried full welded ball valves can have long service life.

3. For connection type, buried full welded ball valves have three types, including welded connection, wire connection and flange connection.

Advantages of buried full welded ball valves

1. Emergency sealing grease ambulance: because of the accidental failure of valve seat caused by media objects or fire accident, greasing valve provides a fast connection to grease gun so that the pump can inject the sealing grease to the sealing parts easily and quickly, easing leak problems.

2. Reliable stem sealing: in addition to the standard sealing ring, there is also an O-ring sealing ring at the packing gland so as to double ensure the reliability.

3. Full bore or reduced diameter: you can use the full bore or reduced diameter structure according to the need. For full bore valve, its flow aperture is consistent with the pipeline inner diameter, which is easy to clean the pipeline.

4. Stem can be lengthened: according to installation or operation needs, the valve stem can be lengthened. And the lengthened stem is especially suitable for city gas and other occasions which need underground laying pipelines. What’s more, extended size is determined by customers’ needs.

5.Flexible operation: with small friction coefficient and good self-lubricating properties of the valve seat and stem bearings, it will greatly reduce the operating torque. Therefore, for buried full welded ball valves, you can flexibly operate the valve freely for a long period even without sealing grease.