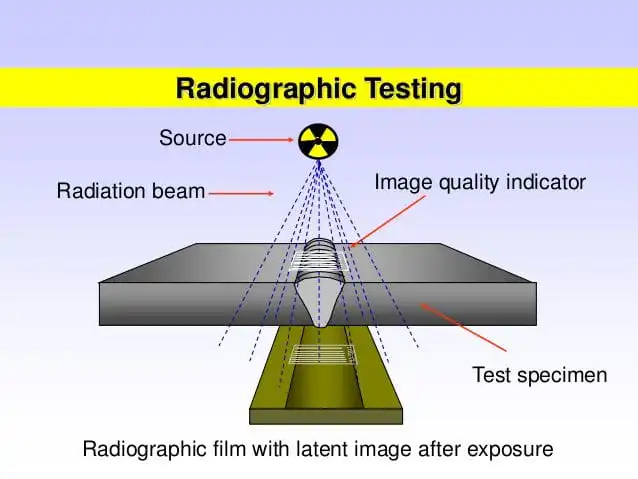

Then, what's RT? What will be the benefits by carrying out RT?

Radiographic Testing is a non-destructive examination (NDE) technique that involves the use of either x-rays or gamma rays to view the internal structure of a manufactured component to identify any flaws or defects.

Once flaws or defects were found in gate valves, defects shall be removed by suitable method such as grinding, chipping or gouging (if permitted). Welding of the repair area shall meet the requirement of related WPS, PQR.

And radiography has several advantages. It is highly reproducible, can be used on assembled components, to verify internal flaws on complex structures. Besides, it can detect defects on both surface and subsurface. The most important thing is that the data gathered can be stored for long time for later analysis.