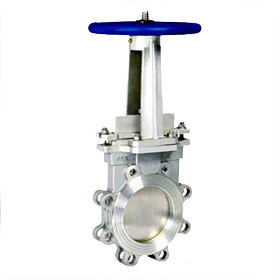

1. Overview of Knife Gate Valve Structure

Before analyzing the faults, it is essential to briefly understand the core structure of the knife gate valve:- Gate (Knife Blade): Designed with a "cutting edge," it can effectively cut through media containing particles or fibers.

- Seal Structure: Typically uses flexible elastomer seals or metal hard seals.

- Valve Body: Mostly of a straight-through design to facilitate media flow, some valves are equipped with self-cleaning channels.

- Actuation Mechanism: Commonly operated manually, electrically, or pneumatically. Knife gate valves are designed with a focus on wear resistance and anti-clogging, but their sealing and structural rigidity are relatively weaker compared to conventional gate valves.

2. Common Fault Types and Causes

(1) Seal Leakage (Internal/External)

•Internal Leakage (Media Leaks After Gate Closure)Cause Analysis: Internal leakage is typically caused by wear or damage to the seal faces between the gate and valve seat, leading to seal failure. Additionally, the media may contain solid particles or impurities that become trapped between the seal faces, causing leakage.

Solution: Perform a pressure test to identify the leak point after closing the valve. For worn seal faces, repair or replace the seals with suitable flexible elastomer or metal hard seals. To prevent clogging by particles, regularly clean the valve body and replace seals as needed. For high-frequency usage, consider using metal hard seals to improve sealing performance.

•External Leakage (Leaks at Valve Body or Packing Area)

Cause Analysis: External leakage typically occurs in the valve body at the packing area, mainly due to packing wear or loose packing gland, which fails to adequately seal the media. Additionally, casting defects such as sand holes or tiny cracks in the valve body may also cause external leakage.

Solution: Regularly check the tightness of the packing and ensure it is not loose. If necessary, re-tighten or replace the packing. For severely aged packing, replace it with high-performance graphite packing or a V-type packing with elastic support. If cracks or sand holes are found in the valve body, conduct a penetration test and, depending on the situation, perform welding repairs or replacement.

(2) Difficult Operation or Jamming

•Gate JammingCause Analysis: Gate jamming usually occurs when the valve has been in the closed position for an extended period, and solid particles or sediment in the media block the valve chamber or gate guide tracks, preventing smooth gate movement. Additionally, the guide tracks may become deformed or eccentric, causing jamming.

Solution: Regularly cycle the valve to prevent jamming from long periods of inactivity. For media containing solid particles or mixtures, periodically flush the valve chamber to remove sediment. Check for deformations in the guide tracks and, if necessary, adjust and correct them to ensure smooth gate operation. For fouling-prone conditions, use knife gate valves with self-cleaning devices or scraper mechanisms.

•Failure of the Actuation Mechanism

Cause Analysis: The failure of the actuation mechanism may result from faults in the hand wheel or electric actuator, preventing sufficient torque to open or close the valve. Wear or binding in the valve stem threads can also prevent the actuation mechanism from functioning smoothly. Additionally, insufficient air or hydraulic pressure in pneumatic or hydraulic actuators can lead to failure.

Solution: Disassemble and inspect the actuation mechanism, cleaning and replacing lubricants as necessary to ensure smooth operation of all moving parts. Check the air or oil pressure and ensure stable output. If the issue is with the pneumatic or hydraulic actuators, check the pressure regulator, adjusting or replacing components as needed. For frequent operation scenarios, consider using high-efficiency, low-friction electric actuators.

(3) Gate Fracture or Deformation

•Gate FractureCause Analysis: Gate fractures typically occur due to insufficient thickness, where the gate is unable to withstand high-pressure differentials or shear forces from hard solid particles. Especially when dealing with high-pressure or high-hardness media, the gate may suffer from excessive impact forces or fatigue failure due to repeated operation.

Solution: Select gates with appropriate thickness and material based on the specific operating conditions. For high-pressure or hard particle-containing media, consider using alloy steel, carbon steel, or other wear-resistant materials for the gate. Ensure the gate is not subjected to improper external forces during installation to avoid "hard cutting" incidents. For conditions prone to damage, regularly inspect the gate and promptly replace any damaged components.

Cause Analysis: Gate deformation typically occurs when the valve is subjected to improper operational torque or uneven working pressure. Long-term high-pressure differentials or mechanical stresses can lead to plastic deformation of the gate material.

Solution: Regularly inspect the gate’s operational status and deformation. If the deformation is severe, replace the gate immediately. When selecting the valve, choose an appropriate pressure rating and material based on the specific working conditions to avoid gate deformation under high pressure. For large-size knife gate valves, enhance monitoring during installation and operation to prevent excessive force application.

(4) Gate Rebound or Incomplete Closure

•Gate ReboundCause Analysis: The primary cause of gate rebound is insufficient elasticity of the sealing ring, preventing proper compression against the sealing surface. If the proper torque or stroke is not applied during operation, the sealing surface may not fully engage, resulting in incomplete closure.

Solution: Check and adjust the closure torque to ensure that the gate can fully compress the sealing surface during closure. Based on the operating environment, replace the sealing material with a more elastic type, or use metal elastic seals to improve sealing performance. Consider adding stroke limiters to ensure proper closure with every operation.

3. Preventive Maintenance Recommendations

| Maintenance Item | Frequency | Recommended Actions |

| Packing Gland Check | Monthly | Inspect tightness and check for leakage |

| Valve Chamber Flushing | After each operation | Prevent slurry and sediment accumulation |

| Gate Lubrication (if applicable) | Quarterly | Use high-temperature lubricants or graphite powder |

| Actuator Inspection | Semi-annually | Check thrust output and stroke errors |

| Comprehensive Leak Test | Annually | Test internal and external sealing integrity |