The overview of the project

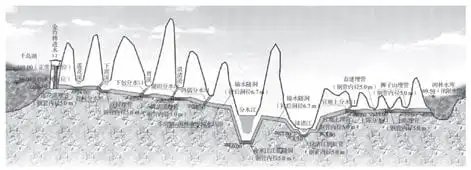

The water distribution project of Qiandao Lake, the second water source in Hangzhou, draws water from the territory of Qiandaohu Town, Chun'an County, and diverts the water to the Xianlin Reservoir in Yuhang District, Hangzhou City through a water transfer tunnel, with a total length of 113.22km. The concrete lining section of the water transfer tunnel is about 102.29 km, and the steel lining section and buried pipe section of the remaining shallow tunnels are about 10.93 km. The entire line is closed, and the water is drawn by the height of the water. The whole line is equipped with 5 sets of DN5000 manual and electric butterfly valves as accident maintenance valves, of which 4 sets have nominal pressure of 1.4MPa, which are located in the underground maintenance valve rooms on the left and right banks of the Fenshui River and the underground maintenance valve rooms on the left and right banks of the Luzhu River. One set with nominal pressure of 1.0MPa is located in the buried pipe section of Shizishan. When the water pipeline supplies water normally, the maintenance valve is in a fully open state; when the water pipeline needs maintenance and repair, the maintenance valve is closed to cut off the water flow. In addition to being used for segmented maintenance along the project, the maintenance valve can also be used for water filling and drainage control. The schematic diagram of the longitudinal section of the water delivery tunnel of the Qiandao Lake Water Distribution Project is shown in Figure 1.

Figure 1 Longitudinal section of water delivery tunnel of the water distribution and water supply project for Qiandao Lake

The water distribution project of Qiandao Lake, the second water source in Hangzhou, is a major livelihood project to ensure the safety of the water supply in Hangzhou and improve the quality of drinking water. The maintenance valve is an important safety barrier for the maintenance and maintenance design of the water pipeline, and its structure and performance are of great significance to the project. The installation position of the maintenance valve is a key position, which plays an important role in the water diversion and drainage of the entire water pipeline.

2. Types and design parameters of butterfly valves

Types and design parameters of butterfly valves are shown in Table 1.

Table 1 Types and design parameters of butterfly valves

| Items | Design requirements |

| Types | Double eccentric butterfly valves |

| The arrangement of the valve shaft | Horizontal shaft arrangement |

| Operation | Manual and electric operation |

| Water stopping methods | Rubber soft seals |

| Nominal diameters | DN5000 mm |

| Maximum hydrostatic pressure | 1.15MPa |

| Maximum hydraulic pressure | 1.25MPa |

| Design pressure | 1.40MPa |

| Design flow | 51.5 m/s (long-term stable operation) |

| Maximum design flow | 90.0 m/s (long-term stable operation) |

| Resistance coefficient at a fully opened state | Less than 0.12 |

| Opening time | 5 to12 minutes |

| Closing time | 5 to12 minutes |

| The strength test of the valve body | 2.1MPa |

| Leakages of positive sealing | 1.54MPa (zero leakage) |

| Leakages of reverse sealing | 0.84 MPa (zero leakage) |

| Body materials | Q345C steel plates and 25 forged steel group welding |

| Disc materials | Q345C steel plates and 25 forged steel group welding |

| Valve shaft materials | 40Cr outer surface surfacing stainless steel |

| Body seal ring materials | 06Cr19Ni10 |

| Materials of butterfly plate's sealing ring | EPDM |

| Electric actuators | IQ95/IW17(Rotork) |

3. The overall structure and working principle of the valve

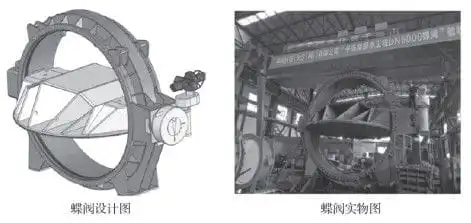

The overall structure of the valve: the butterfly valve is mainly composed of the valve body, the butterfly plate, the valve shaft, the bearing parts, the shaft seal parts, the water-stop sealing pair, the electric actuator and other parts. The design and material object of the butterfly valve is shown in Figure 2. The butterfly valve adopts a double eccentric structure: the first eccentricity is to offset the center of rotation of the valve shaft from the sealing center of the valve body by a certain distance, so that they do not interfere with each other.

The second eccentricity is that the center of rotation of the valve shaft is shifted upward by a certain distance from the center line of the valve body. The water-facing area of the middle and lower half is larger than that of the upper half in the closing process, which helps the valve to close.

Figure 2 Design drawing and physical drawing of butterfly valves

Working principles: The valve shaft is driven by the electric actuator to drive the butterfly plate to rotate within a range of 90° to realize the opening and closing of the valve. The fully open position flows through water, and the fully closed position contacts the stainless steel sealing seat on the valve body through the solid rubber sealing ring on the butterfly plate to form a water-stop seal to cut off the water flow.