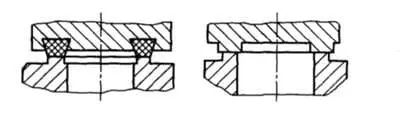

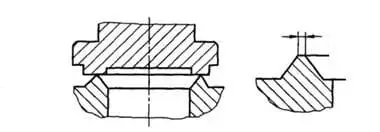

1. Plane sealing: As shown in the picture, the two contact faces of the sealing face are plane. This type is easy to manufacture and maintain. When used on the globe valve, there is no friction at the moment of closing, but the axial force of the valve stem is large.

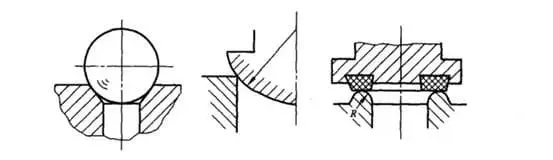

2. Conical sealing: As shown, the two contact faces of the sealing face are taper face. This kind of sealing face is the same as the plane seal, a higher sealing force can be obtained, and the sealing performance is good. The cone seal is generally used on a high-pressure, small diameter valve (such as a needle valve and a plug valve).

3. Spherical sealing: As shown in the picture, the two contact faces of the sealing face have one (line contact) or two (face contact) as spherical surfaces. This type of seal is good, but it is difficult to manufacture and maintain. Ball valves and globe valves are used more.

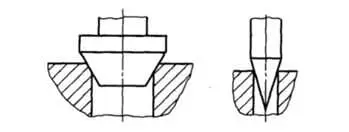

4. Knife sealing: As shown, one of the two contact faces of the seal is a knife-edge shape, which is a seal between the line and the plane contact. This form of sealing has small sealing force under conditions such as a vacuum valve.

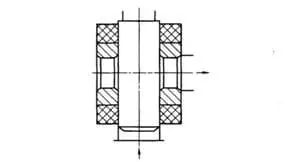

5. Cylindrical sealing.